What is Flexible FPC?

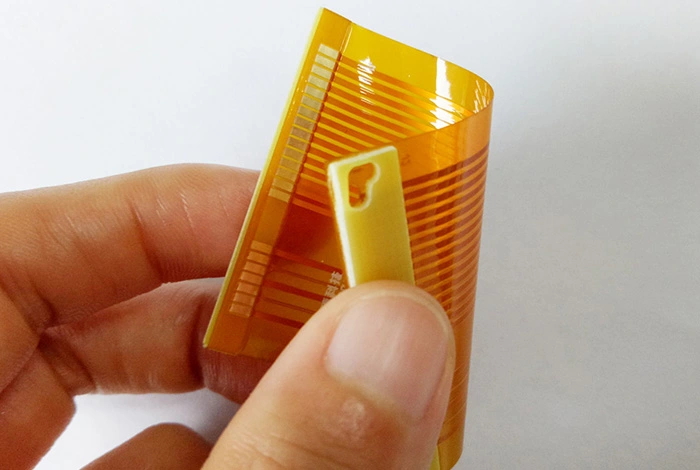

Flex FPC or Flexible Printed Circuit is a type of FPC designed to bend and flex to fit into tight spaces. Flexible FPCs are made of flexible materials such as polyimide and are used in applications where space is limited and flexibility is critical, such as wearable devices, smartphones, and medical devices.

Single-sided flexible FPC

Structure: Single-sided flexible FPC has a conductive layer on one side of the insulating substrate. The other side remains bare or covered with a protective layer.

Applications: For simple, low-density designs such as basic consumer electronics and appliances.

Advantages: Easier and cheaper to manufacture, making it ideal for cost-sensitive applications.

Limitations: Limited circuit complexity and fewer connection options compared to double-sided or multi-layer designs.

Double-sided flexible FPC

Construction: These FPCs have conductive layers on both sides of the insulating substrate. They allow for more complex and compact circuits.

Applications: Suitable for designs of medium complexity, including telecommunications, automotive, and medical devices.

Advantages: Greater design flexibility, higher wiring density, and the ability to mount components on both sides.

Multilayer flexible FPC

Structure: Multilayer flexible FPC has three or more conductive layers separated by insulating layers. These layers are interconnected through vias to form more complex structures.

Applications: Used in high-density, high-performance applications such as advanced medical equipment, aerospace systems and high-end consumer electronics.

Advantages: Highest routing density, best performance, and greatest design flexibility.

Limitations: Most complex and expensive to manufacture, requiring advanced manufacturing techniques and materials.

Common applications of flexible FPC

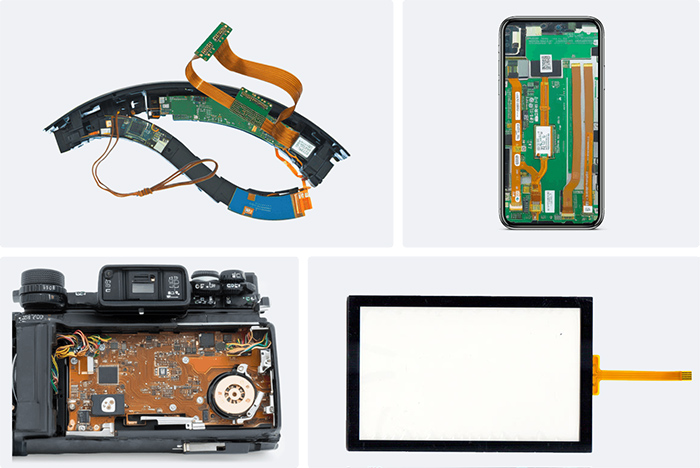

Wearable technology: Flexible FPCs are ideal for wearable devices such as fitness trackers, smart watches and medical monitors. Their flexibility allows them to adapt to the shape of the human body, providing comfort and durability in dynamic environments.

Consumer Electronics: Flexible FPCs are widely used in smartphones, tablets, notebooks, and cameras. They help reduce the size and weight of these devices while allowing for more compact and sophisticated internal designs.

Automotive Systems: In the automotive industry, flexible FPCs are used in instrument panels, control systems, sensors, and LED lighting. They are suitable for automotive applications because they can withstand vibrations, extreme temperatures and harsh conditions.

Medical Devices: Flexible FPCs enable smaller, more comfortable, and more biocompatible designs in implantable devices, diagnostic equipment, and medical sensors, improving patient care and treatment outcomes.

上一篇: 没有了!